Knowledge base

General Info

Factors to affect RPM and Feed

- Rigidity of Machine Spindle

- Max. RPM of Machine Spindle

- Max. RPM of Machine under the circumstance of best dynamic balance

- Capability of pre-read program on Controller

- Max. feed of Machine

- Accuracy of Collet Chuck & Collet

- Rigidity of Collet Chuck & Collet

- Chucking strength of Collet Chuck & Collet

- Dynamic balance of Collet Chuck & Collet

- Type of End Mill

- Material of End Mill

- Rigidity of End Mill

- Overhang length of End Mill protruding from Collet Chuck

- Cutting method of End Mill

- Cutting path of End Mill

- Cutting parameter(depth) of End Mill

- Chip removal capability of End Mill

- Hardness of Workpiece

- ensile strength of Workpiece

- Machinability of Workpiece

- Rigidity of Workpiece

- Rigidity of Clamping Device and Fixture

- Type of Coolant

- Supply way of Coolant

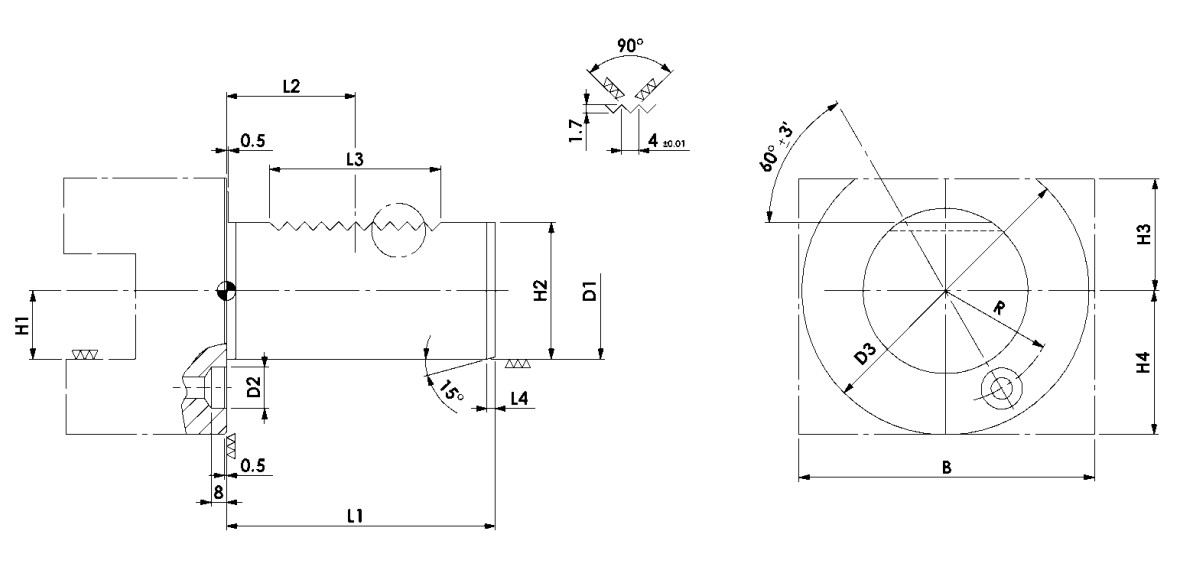

Tool Holder

DIN69880

Unit: mm

| D1 h6 |

D2 | D3 | H1 max |

H2 ±0.05 |

H3 min |

R ±0.02 |

L1 max |

L2 ±0.05 |

L3 max |

L4 max |

| 20 | 10 | 50 | 16 | 18 | 25 | 18 | 40 | 21.7 | 24 | 2 |

| 25 | 10 | 58 | 16 | 23.5 | 25 | 21 | 48 | 21.7 | 24 | 2 |

| 30 | 14 | 68 | 20 | 27 | 28 | 25 | 55 | 29.7 | 40 | 2 |

| 40 | 14 | 83 | 25 | 36 | 32.5 | 32 | 63 | 29.7 | 40 | 3 |

| 50 | 16 | 98 | 32 | 45 | 35 | 37 | 78 | 35.7 | 48 | 3 |

| 60 | 16 | 123 | 32 | 55 | 42.5 | 48 | 94 | 43.7 | 56 | 4 |

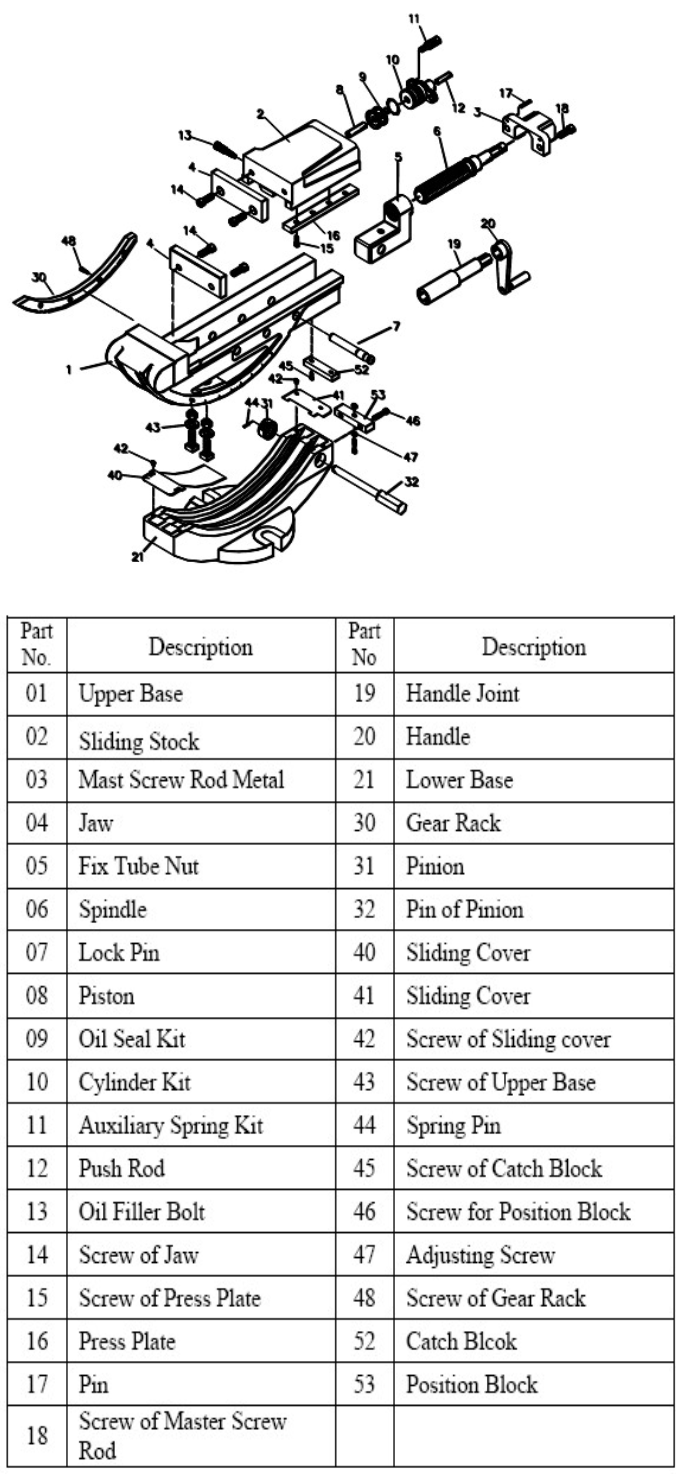

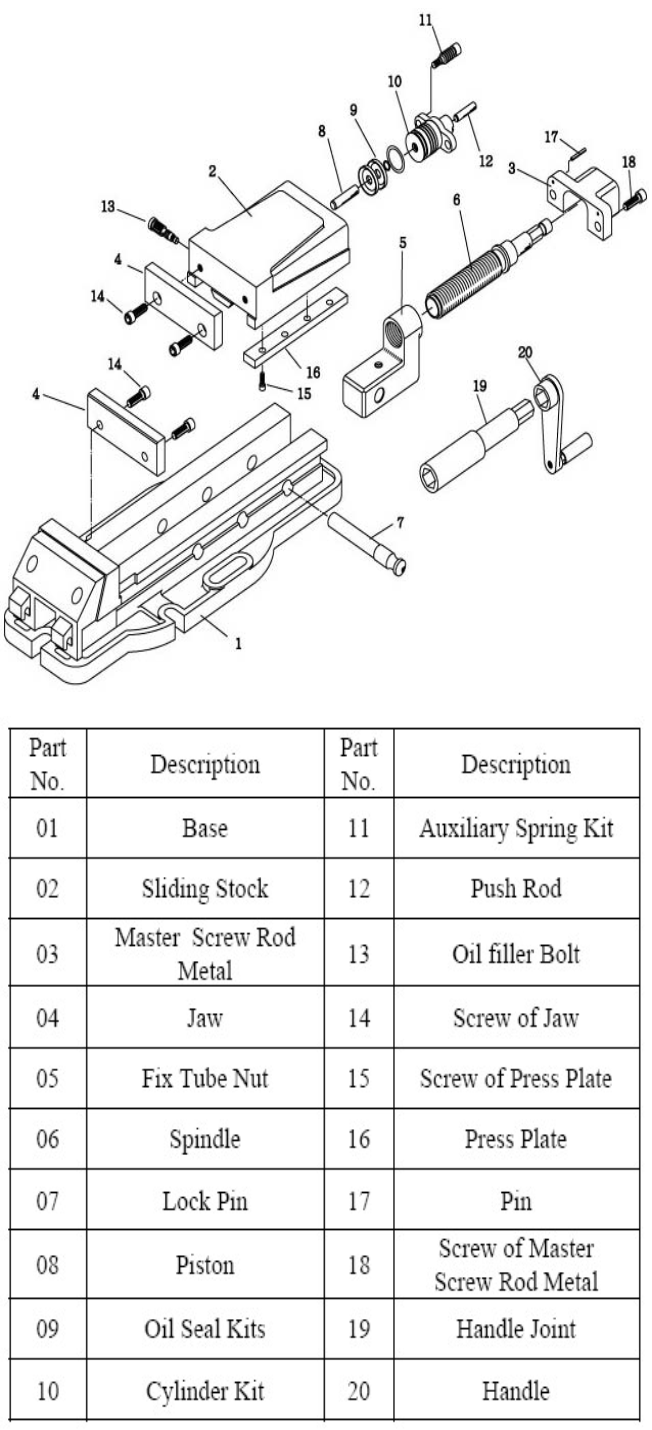

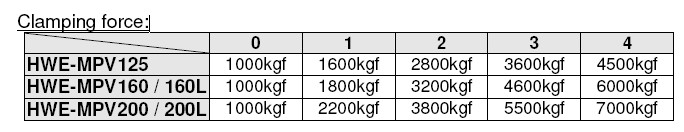

Vise

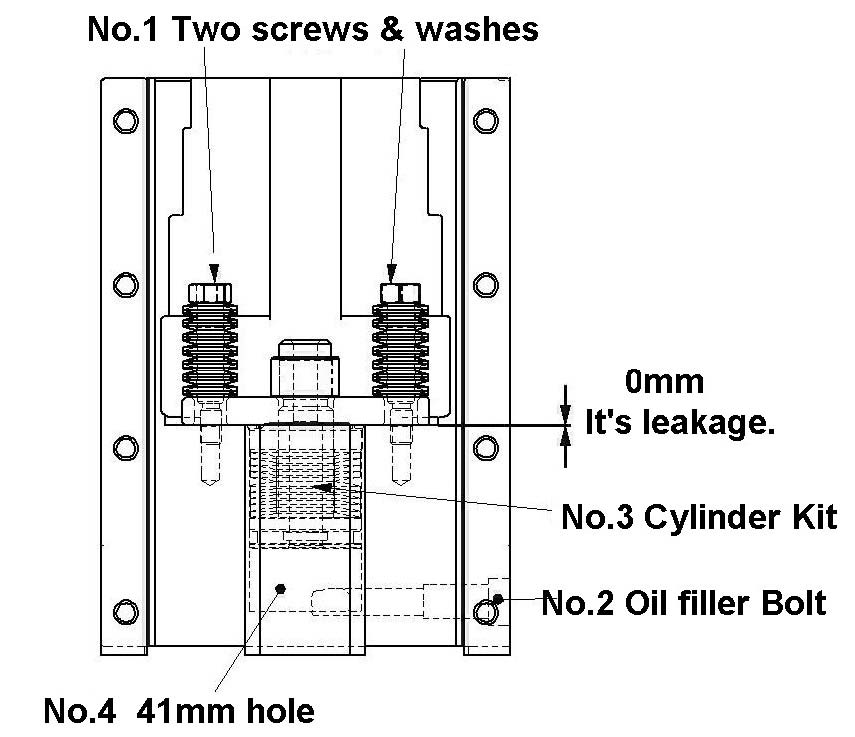

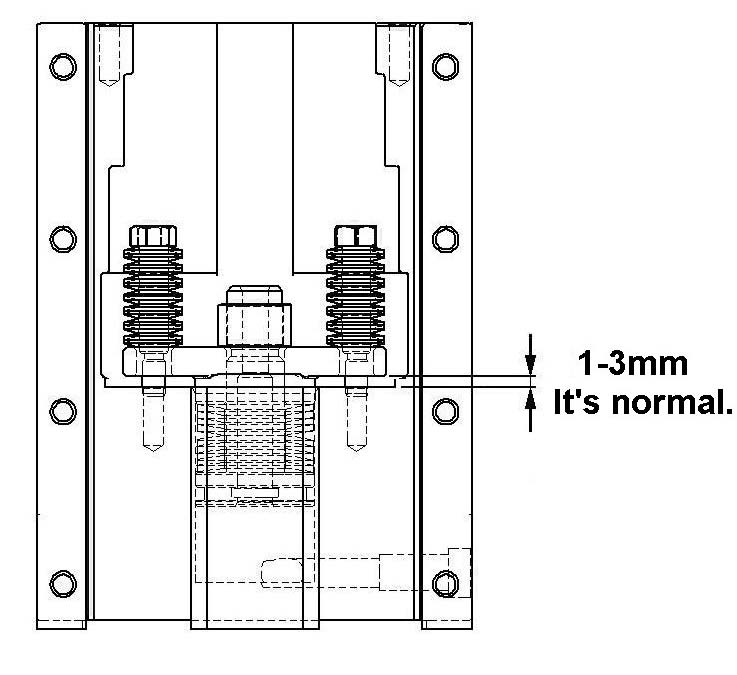

A. How to know whether it is oil-leaking:

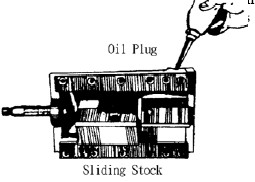

- Pull out the sliding stock from vise body before using the vise and under no hydraulic pressure.

- Check whether it has a gap 1-3 mm or not.

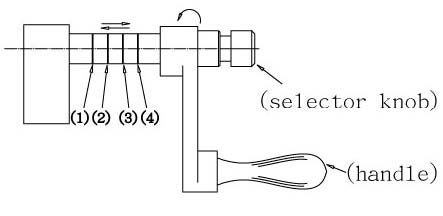

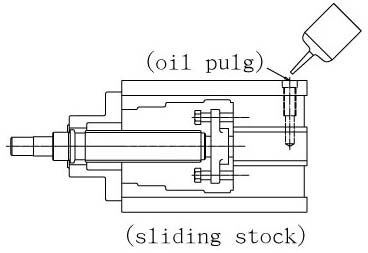

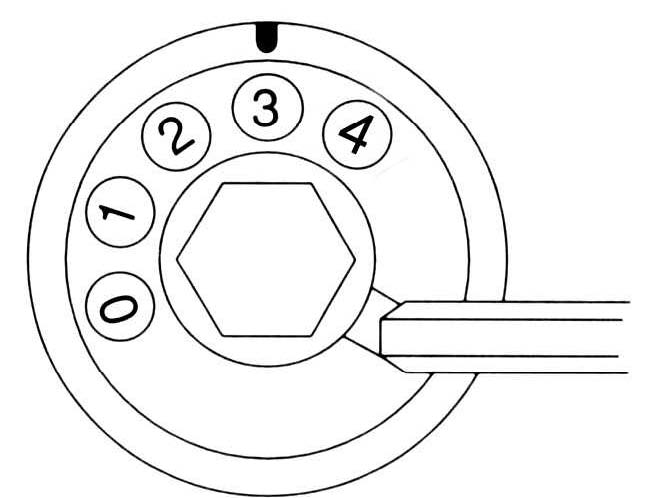

B. How to solve oil-leaking issue:

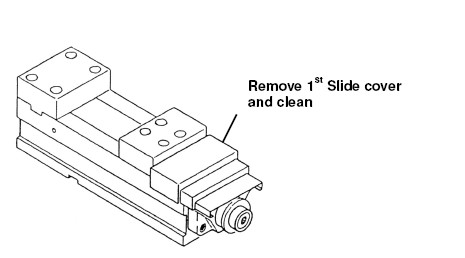

- Please take out two screws and washes (No. 1).

- Take out whole set of oil filler bolt (No. 2).

- Pull out whole set of cylinder kit (No. 3).

- Use magnifier to check whether oil seals are broken or not.

- Use naphtha to clean the hole 41 mm (No. 4) where cylinder kit can put in, and then dry it by compressed air.

- Even spread grease on the cylinder kit, and then put it in the hole 41 mm.

- Keep a gap 2-4 mm and slant the sliding stock a little bit, then fill oil in.

- Shake sliding stock lightly to let air come out from oil hole. Please ensure there is no air inside the oil hole.

- Screw whole set of oil filler bolt (No. 2), and then screw two screws and washes (No. 1) tight.

- The last step is to install spindle, fix tube nut, and the vise body. After installation, please check its clamping force again.